DOBOT Cobots

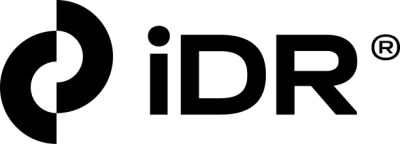

Reliable, versatile collaborative robots designed for seamless integration into your production line.

What are DOBOT Cobots?

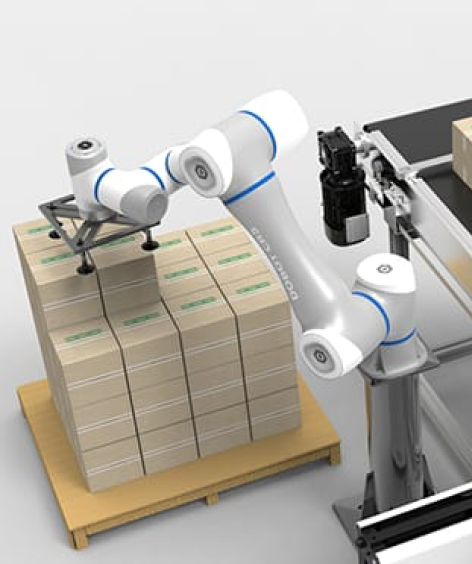

DOBOT Cobots are collaborative robots designed to work safely, flexibly, and efficiently alongside humans. Unlike traditional industrial robots that operate in isolation for safety reasons, DOBOT Cobots integrate advanced monitoring technologies—such as impact sensors, capacitive sensors, and cameras—that allow them to detect human presence and adjust their movements in real time, ensuring a safe working environment.

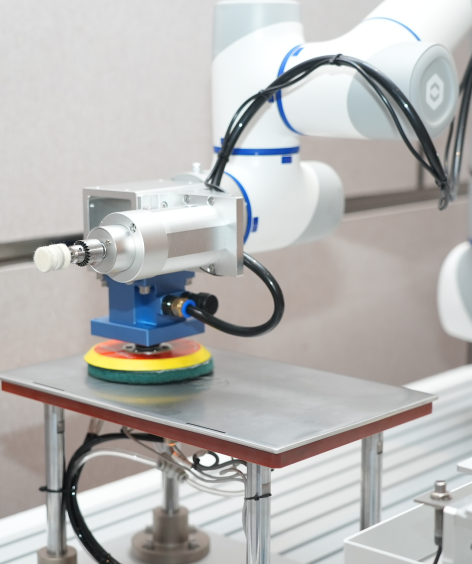

This capability makes them ideal for automating repetitive, heavy, or potentially hazardous tasks, freeing operators to focus on more complex and creative activities. DOBOT Cobots are widely used across industries such as manufacturing, logistics, healthcare, food, and services, contributing to safer, more ergonomic, and productive workplaces.

Advantages

✓ Wide Payload and Reach Capacity: Supports payloads from 0.5 kg to 25 kg with a working radius between 440 mm and 1700 mm, adapting to various industrial applications.

✓ Built-in Safety: Equipped with impact sensors, proximity detection, and automatic stop systems that ensure a safe working environment without the need for physical barriers.

✓ Intuitive Programming: Simple interfaces and block-based language make programming easy, even for users without robotics experience. The software is free and compatible with multiple platforms.

✓ Fast Integration: Compatible with equipment such as CNC machines, welding machines, PLCs, AGVs, and AMRs, without requiring significant infrastructure changes.

✓ Increased Productivity: Automates repetitive tasks, freeing employees for higher value-added roles and reducing waste.

✓ Versatility and Flexibility: Easily reprogrammable for assembly, packaging, welding, quality inspection, and more.

✓ Quick Return on Investment: More affordable than traditional industrial robots, with fast implementation and low energy consumption. Estimated payback period is less than one year.

✓ Improved Working Conditions: Performs dangerous or physically demanding tasks, reducing injury risks, improving ergonomics, and promoting a safer, more comfortable work environment.

✓ High Precision and Consistency: Advanced sensors ensure precise, repeatable movements, enhancing process quality and efficiency.

✓ Energy Efficiency: Low energy consumption reduces operational costs and supports sustainability.

Technical Applications:

Explore the different applications: click the icons to see the cobot in action.

Estimated payback period — less than one year.

Application Sectors

Want to learn more about Cobots?

Check out our blog articles on the topic and stay updated with the latest industry news.

Empower your team with the collaboration of our Cobots!

Send us your message and discover how collaborative automation can transform your operation with fast and effective solutions.